The orbital sander is a power tool portable that works in a direction of rotation random widely used today both in industry as a diy. We can find them electric or pneumatic.

Appeared at the beginning of the TWENTIETH century and quickly became extraordinarily helpful.

These sanders combine portability along with the speed and aggressiveness of a belt sander automatic bands, having, in addition, the ability to produce a fine finish.

WHAT IS AN ORBITAL SANDER?

An orbital sander is a tool for sanded or polished portable electric or pneumatic actuated widely used in treatments of surfaces such as wood, metal, composites, plastics, etc...

Have devices to regulate the speed with which it can be sanded, measures that range between 8,000 and 12,000 rpm, being the speed range more typical of 10,000-12,000 rpm.

In the case of the sander pneumatic regulator air inlet, or in the case of the electric sander speed regulator, allows to adapt the tool to the work that we perform optimizing the speed of rotation required. In this ratio to greater speed, better finishes, while conversely at higher speeds reduced largest power of cutting and trimming.

The orbital sanders and the sanders eccentric, also called rotoorbitales are light tools, so that they can be handled with extreme accuracy and can be transported very easily. His usual ergonomic design offers a very comfortable and intuitive, and its use does not require great efforts.

An orbital sander can be used for grinding, sanding, tinting and polishing surfaces, as well as get to open the pores of different materials and to improve the adhesion of the paint.

ORBITAL SANDER OR BROKEN ORBITING WHAT TO CHOOSE?

Orbital sanders

With a single motion, circular.

The orbital sanders are specified for sanding flat surfaces and a bit curved. Actually created for works of finishes.

The orbital sanders provide quickly a fine sanding.

Sanders rotoorbitales or eccentric

With a circular motion accompanied by an eccentric movement, rotate and orbit at the same time.

The general concept is the result of a movement of rotation of the disk lijador simultaneously with a movement of ellipses of the machine, ensuring that the abrasive does not repeat twice for the same point of the surface. Thanks to this action of sanding surfaces, random, the tool does not leave swirl marks.

Sanders rotoorbitales are better suited for jobs roughing it, thanks to this movement, the work of the abrasive is more direct to the treated surface. Very useful to remove paints and varnishes old for this type of eccentric movement that attacks more directly to surfaces.

With sanders eccentric are getting the best results when you perform work of trimming.

HOW TO USE AN ORBITAL SANDER?

1.- The sander must always be parallel to the surface during use, with a movement that is constant, avoiding at all times to keep it in the same place as it may generate irregular marks.

In the same way we must not tilt the sander to act with the perimeter of the base of the dish.

2.- Turn on the ignition of the sander once it is resting on the surface to be treated, and turn it off or disable it when we have withdrawn from the same.

3.- Use the pressure of sanding adequate, should not be excessive. You must allow that the displacements on the surface are natural and not forced, avoiding overheating the surface and sanding the poor.

4.- Avoid making sudden movements. It is advisable to sand the surface first with displacements of up and down, and then with movements from right to left. To secure that there are no areas without sanding is recommended movements of overlapping passes of about 2-3 cm each.

5.- To review the abrasive frequently to make sure that there are no folds or contaminated areas, breaks, or embozamientos that may cause marks during the sanding.

6.- Clean the dust from the surface before you begin to perform the task.

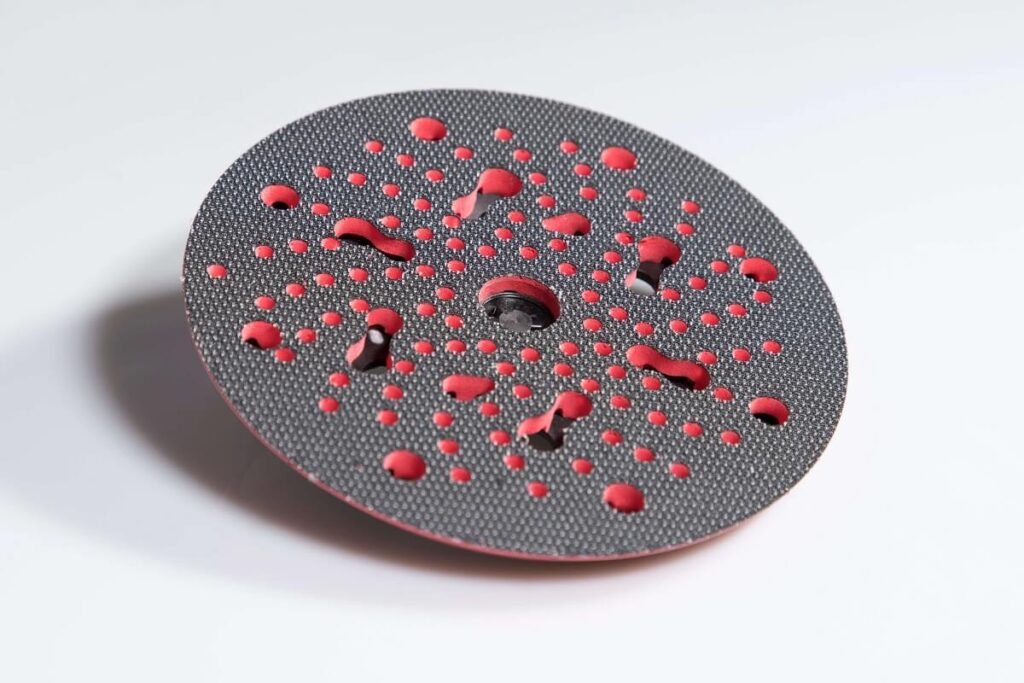

NOTE: For the accession of the disks to the dish the belt sander is the use of two types:

-

Dishes for discs velcro. Using a system of hook velcro.

-

Dishes disk adhesives. The discs are adhered to the plate of the belt sander using glues of contact.

CHECK OUT OUR CATALOG OF DISHES

“THE ORBITAL SANDERS PROFESSIONAL AND DIY USE ABRASIVE DISCS AND DUST EXTRACTION SYSTEMS”

THE FUNCTION OF ALL THE SYSTEMS OF ASPIRATION

Primarily as a measure of job security for the operator, to keep the work environment clean, sound and free of dust and particles.

Another reason, and no less important is the subtract unnecessary costs of time cleaning in the area or workplace.

For these reasons, the orbital sanders and rotoorbitales of the market have ducts and extraction hoods for the collection of particles and dust caused.

Mainly we find two vacuum systems:

- The most economical and most easy is a bag of paper or cloth, disposable placed in the back of the sander, and that takes advantage of the own flow of air generated to vacuum the dust and particles that exist.

- And the vacuum system more professional and efficient with the help of a team of aspiration, self-contained. These systems can you find them portable or stationary depending on the use that they are going to give.

CONSULT OUR PROPOSAL IN SANDERS